Information for Customers Considering the Introduction of Melting Furnaces and Heat Treatment Equipment

What HIROCHIKU Can Do for You

Our Strength

HEAT TECHNOLOGY

HIROCHIKU responds to the diversifying needs of the industry with high-quality, energy- and cost-saving performance and environmental improvements using HIROCHIKU’s Thermal energy technology as its technical core.

Aluminum and Non-Ferrous Metals (e.g., copper and zinc)

Design, manufacture, installation, and support of die-casting manufacturing equipment.

New Materials (e.g., polycrystalline silicon and lithium-ion battery)

Sales and support of heat treatment equipment used from research to manufacturing

Steel and Non-Ferrous Metals (e.g., aluminum, stainless steel, and steel)

Sales and support of heat treatment equipment

Three Equipment Brands to Support Customers

Our Proposal

Proposal by Customer’s Industry

Four Wheels / Two WheelsAutomobile production, motorcycle production, related component production, etc.

Sales and maintenance of engines, brakes, and interior and exterior component manufacturing equipment (e.g., melting and dosing furnaces and automatic molten metal distribution equipment)

Sales and maintenance of equipment for the development and production heat treatment equipment for materials, such as brake pad materials, lithium battery materials, and rare earth magnets

Sales and maintenance of various types equipment for heat treatment (e.g., hardening, tempering, annealing, softening, hardening) for brake pipes, fuel supply pipes, exhaust pipes, etc. and continuous brightening brazing

Industrial ProductsE.g., trains, aircraft, construction machinery, machine tools, and precision machinery

Sales and maintenance of manufacturing equipment for die-casting parts, including transportation equipment, home appliances, personal computers, cameras, and fasteners

Sales and maintenance of heat treatment equipment for the development and production of materials, including ceramics, such as alumina, zirconia, and SiC, as well as dissimilar metal joining and powder injection molding

Sales and maintenance of various types of heat treatment equipment, including those for the quenching and tempering of the chuck parts of machine tools, quenching and tempering of probes for electronic components, and brightening annealing of nickel-based material that drives the hands of watches

Electronic and Electrical MaterialsE.g., LCD panels, semiconductors, solar cells, lithium-ion batteries, ceramics, and electronic substrates, and materials recycled from precious metals

Sales and maintenance of heat treatment equipment, including sintering furnaces for indium tin oxide (ITO) targets and aluminum nitride (AIN) substrates, semiconductor silicon melting furnaces, and analytical furnaces for recycling precious metals, for the development and production of materials

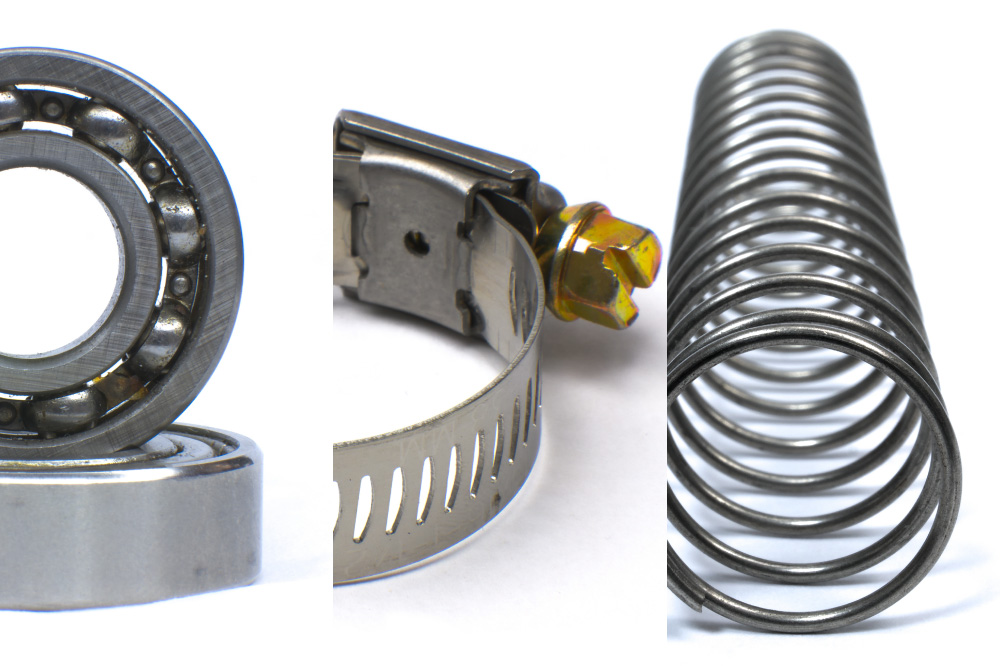

Molds and JigsE.g., press dies, plastic dies, machine tool jigs, blades, dies, and taps

Sales and maintenance of heat treatment equipment for the quenching, tempering, and annealing of mold parts (e.g., punches and dies, guide pins, guide bushes, screws, and washers), jigs for machine tools (e.g., collet chucks, drills, cutters, reamers, and bites), and power tools (hole saws, drill bits, and sockets)

Our Support

Support for Customers

Approach to Implementation

HIROCHIKU makes a set of proposals, ranging from the layout designing to the introduction of equipment, including the new construction of die-casting factories, a review of production processes, and the restructuring of production processes.

Please use sample baking tests (at the RD Center) for research and testing on heat treatment materials, including new materials (e.g., polysilicon, LEDs, lithium-ion batteries, and carbon nanotubes), as well as mass production approaches and equipment tests.

HIROCHIKU offers the best heat treatment equipment through preliminary sample tests for the heat treatment of steel and non-ferrous metals. HIROCHIKU has more than 10 test machines available for technical and equipment proposals.

Operational Support

HIROCHIKU’s maintenance team conducts heat diagnosis, exhaust gas diagnosis, molten metal analysis, and equipment monitoring using the Internet of things (IoT), and provides equipment inspection guidance.

HIROCHIKU offers a heat treatment processing service for heat treatment processes, including those for the continuous brightening annealing and continuous brazing of stainless steel. This is a service to conduct heat treatment on behalf of HIROCHIKU’s plant according to customers’ specifications.

Users can also utilize HIROCHIKU’s plant as a backup factory during their equipment maintenance.

About Maintenance

HIROCHIKU has a maintenance team for each of its three brands.

HIROCHIKU places importance on the maintenance service and conducts regular maintenance procedures, which are essential for maintaining performance, avoiding trouble, and enabling customers to use equipment and facilities comfortably.

HIROCHIKU responds flexibly to sudden equipment issues and gives top priority to customer operations for the supply of replacement parts and equipment.

Holimesy Updating and Maintenance

Technical Consultation and Seminar

HIROCHIKU holds seminars regularly on the basics of heat treatment, heat treatment characteristics of each material, know-how in using HIROCHIKU’s equipment, and the performance of HIROCHIKU products. Please use the seminars for your in-house technical training.

HIROCHIKU’s technical staff in each field will respond. HIROCHIKU looks forward to your technical consultation.

Overseas Support

HIROCHIKU supports the overseas manufacturing bases of domestic companies. HIROCHIKU will introduce various types of melting furnaces and heat treatment equipment and also provide on-site support to them prior to their operation starting.

Furthermore, HIROCHIKU is currently providing extra support to an increasing number of overseas trading companies.

Data Library

Summery of Specifications of Equipment

Melting Furnace, Dosing Furnace and Heat Treatment Equipment for Die-Casting

List of Aluminum and Non-Ferrous Metals Equipment

Features / Melt Supply Capacity / Dosing Capacity

Heat Treatment Equipment for Advanced Material Development

Heat Treatment Equipment of Steel and Non-Ferrous Metals

List of Metal Heat Treatment Equipment

Features / Treated weight / Applications / Temperature

Thermal's Heat Treatment

Heat treatment of steel / Bright heat treatment / Heat treatment of non-ferrous metals / Thermal's philosophy

Aluminum and Non-Ferrous Metal Equipment

Aluminum and Non-Ferrous Metal Equipment New Material Development Equipment

New Material Development Equipment Metal Heat-Treatment Equipment

Metal Heat-Treatment Equipment