Features

Compatible with cutting-edge specifications

Unique products that no competitor in the world can hold a candle to. Reliable support for customers’ engineering stages, ranging from research in new materials to mass production.

Compatible with high specifications

Supporting low to high temperatures (100°C to 2400°C). Responding to customers’ desired environments, ranging from high-vacuum environments to pressurized environments, inert gas atmospheres (such as argon or helium), and reducing atmospheres.

Fitting for Production Lines

Offering tabletop products to large-scale products for production sites, including batch-type and continuous-type furnaces. Also supports the robotic loading and unloading of processed objects.

Batch Furnace

Ultrafast Heating Electric Furnace (SF)

Max. Operating Temperature: 1,700℃

Optional: 1,800℃ Specifications

A compact R&D experimental furnace that can raise the temperature quickly in the atmosphere and operate efficiently.

Large-Scale Fast Heating Electric Furnace (HLF)

Max. operating temperature: 1,700℃

Optional: 1,800℃ specifications

A large-scale R&D and production furnace with good temperature distribution in the atmosphere.

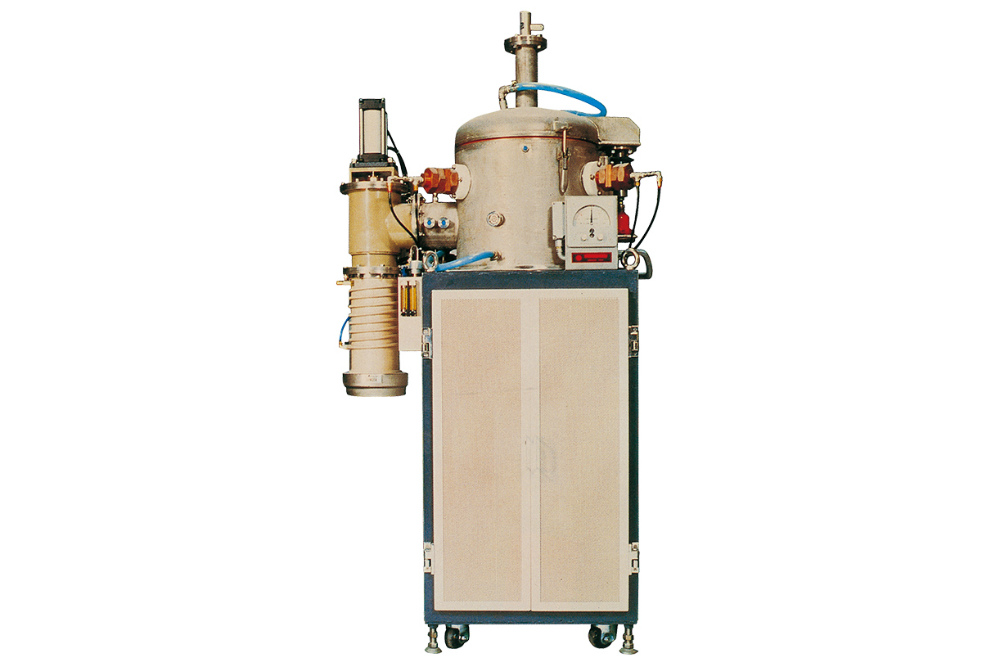

Ultra-High-Speed, High-Temperature Melting Furnace (RMF)

Max. Operating Temperature: 1,650℃

A convenient tabletop R&D furnace of elevator type, capable of introducing inert gas, and ideal for melting glass and metal.

High-Speed Heating Furnace (HAF)

Max. operating temperature: 1,700℃

Optional: 1,800℃ specifications

The HAF Series includes an R&D and production furnace and large-scale furnace, in which various atmospheres can be easily obtained.

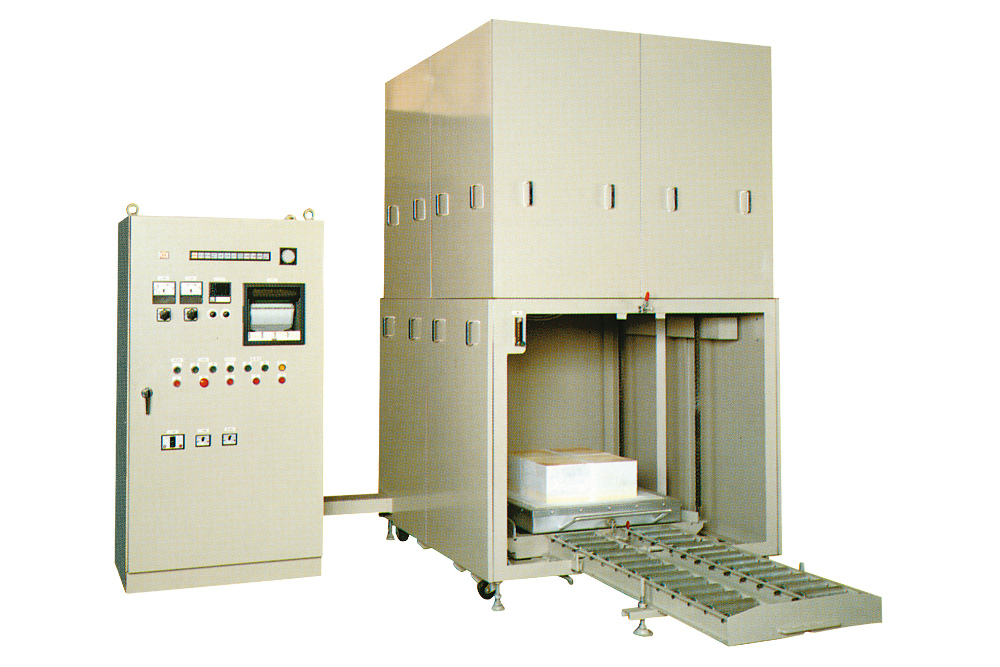

Large-Scale Elevator-Type Electric Furnace (HPF)

Max. operating temperature: 1,700℃

An elevator-type electric furnace developed to increase the size and soaking. This furnace provides uniform soaking for a large amount of sintering at high temperatures and demonstrates excellent performance for research and production.

Multipurpose Atmosphere Furnace (PVF)

Maximum operating temperature: 1,150℃

A versatile atmosphere furnace of completely sealed type using a muffle, and providing a vacuum, oxidizing or reducing atmosphere, and inert gas atmosphere.

High-Temperature Vacuum Atmosphere Furnace (SVF)

Max. operating temperature: 2,200℃

An R&D and production furnace that employs a metal heater and can perform heat treatment in a vacuum, reducing atmosphere, and inert gas atmosphere.

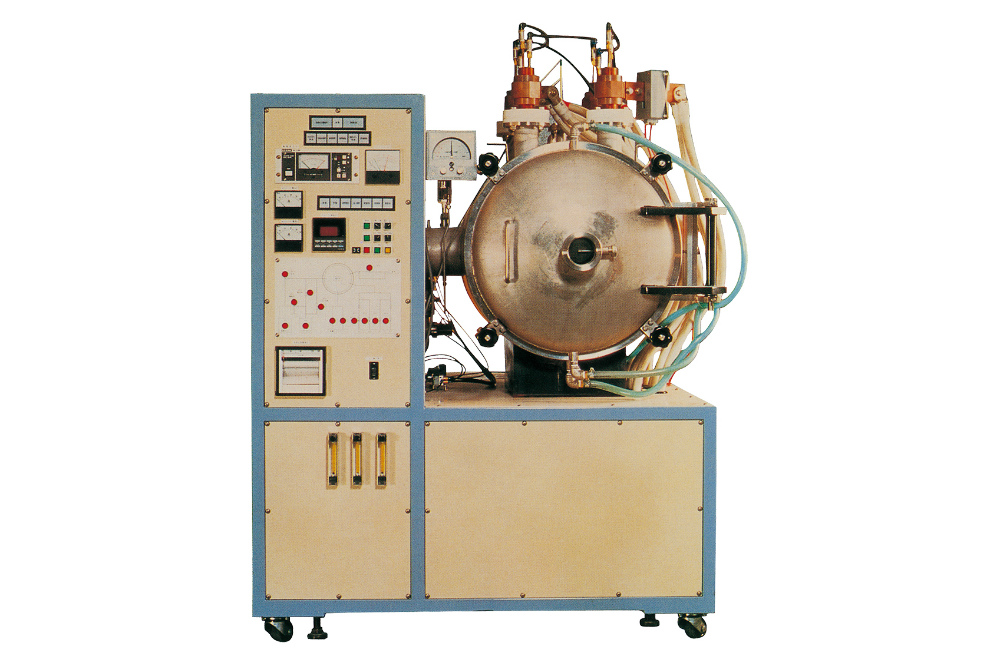

High-Temperature Vacuum Atmosphere Furnace (CVF)

Max. operating temperature: 2,200℃

An R&D and production furnace that employs a carbon heater and performs heat treatment in a vacuum, reducing atmosphere, and inert gas atmosphere.

Atmosphere Hot Press Furnace (AHP)

Max. operating temperature: 2,300℃

An R & D and production furnace that employs a carbon heater and used for pressing at high temperatures in a vacuum, reduction atmosphere, and inert gas atmosphere.

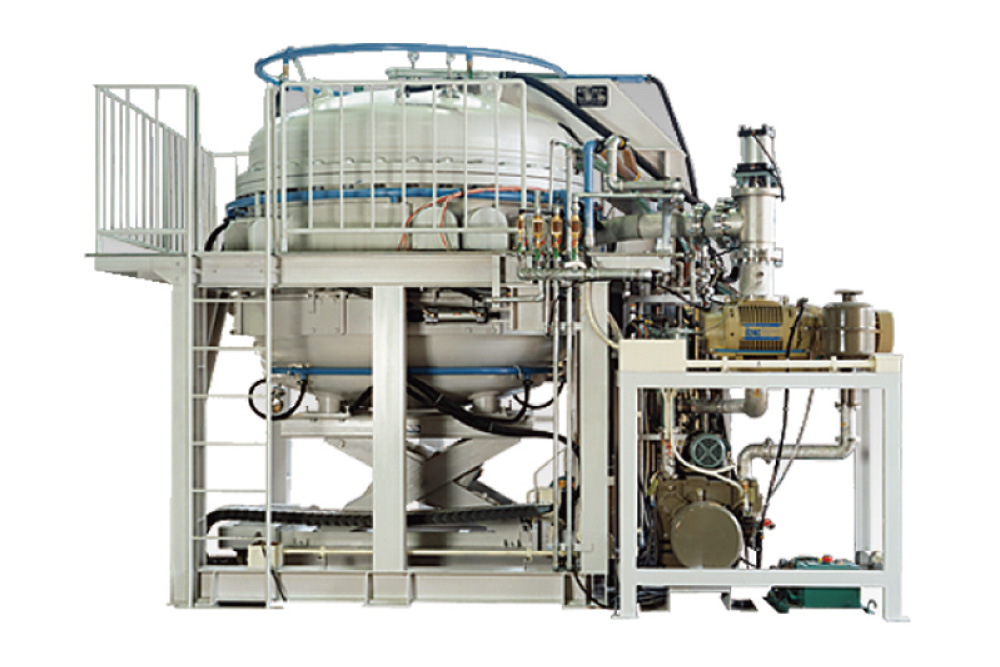

Pressure Sintering Furnace (CMO)

Max. operating temperature: 1,700℃

A sintering furnace that can be used under pressurized atmospheres in a wide range of conditions, including oxidizing and reducing atmospheres. Larger sizes are available.

Batch-type Rotary Tube Furnace

(B-RTF)

Max. operating temperature: 1,000℃

Various powders, such as metal and ceramic powders, can be fired for a long time in an oxidizing atmosphere, reducing atmosphere, and inert gas atmosphere.

Condensing Furnace (OHS)

Max. operating temperature: 1,100℃

Incorporating a reflection module and halogen heater to achieve rapid heating and cooling.

Continuous Furnace

Rotary Tube Furnace (RTF)

Max. operating temperature: 1,600℃

A continuous furnace that is optimal for the heat treatment of powder, used to save heat treatment time, and ideal for the pilot and full-fledged production of various powders.

Atmosphere Rotary Tube Furnace

(A-RTF)

Max. operating temperature: 1,600℃

Making it possible to heat process various types of powders uniformly and continuously in H2 and N2 gas atmospheres.

Walking Beam Furnace (WBF)

A walking beam furnace of the electric heating type, with technology introduced from Klemmer (Germany), boasting abundant delivery records all over the world.

Roller Hearth Furnace (RHF)

Consisting of an inlet replacement, followed by heating, slow cooling, and cooling chambers, outlet replacement chamber, and return table, making firing possible in high-temperature atmospheres.

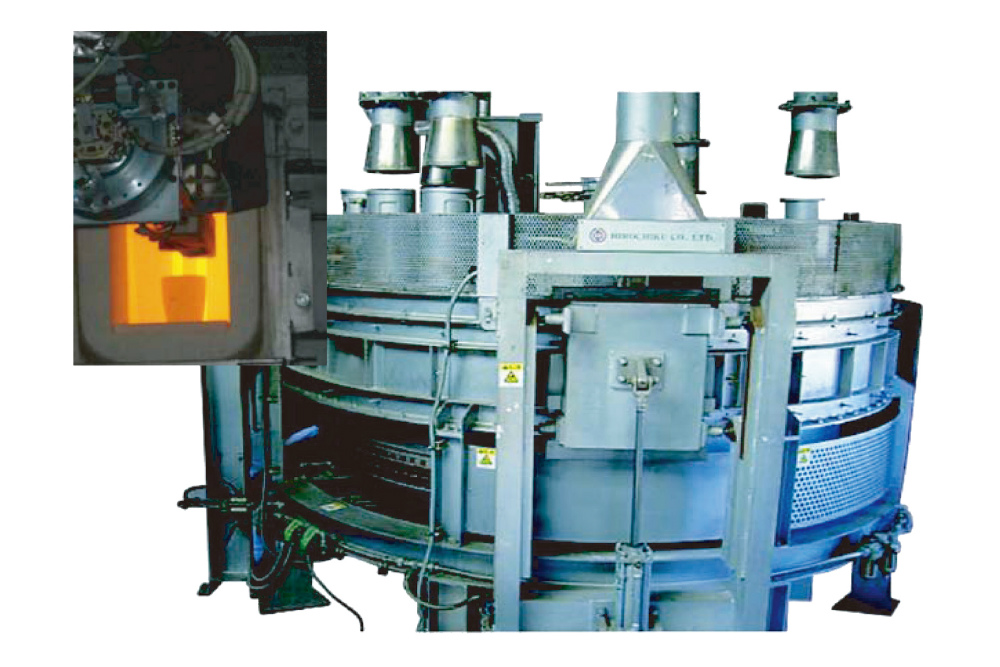

Rotary Hearth Furnace (RF)

A continuous furnace of the rotary hearth type, incorporating an industrial robot, achieving environmental, labor-saving, and accuracy improvements in melting work for Dray analysis.

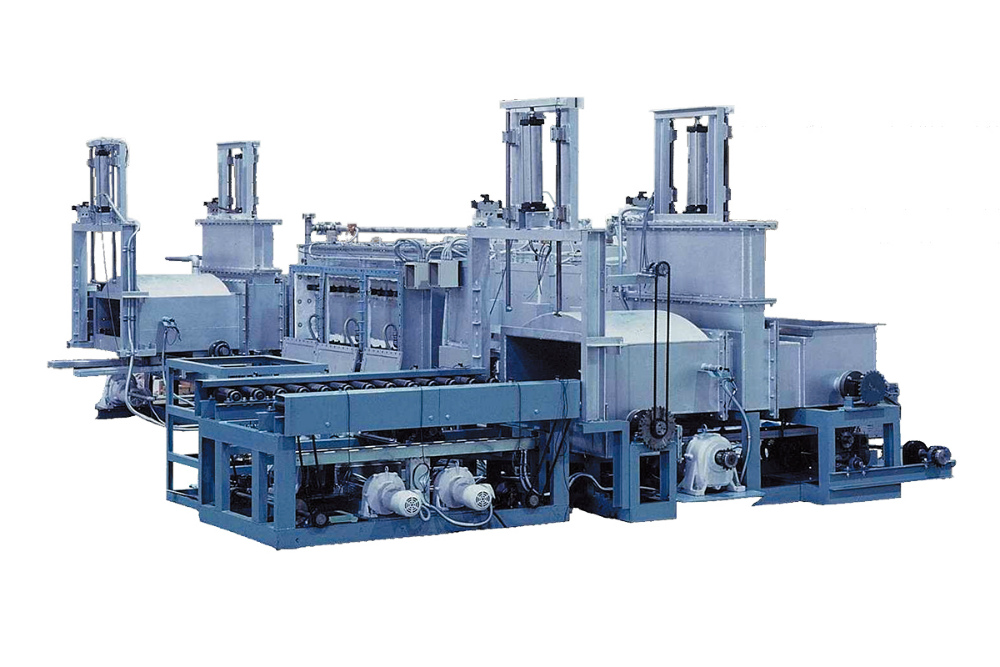

Pusher Furnace (PF)

A pusher-type continuous furnace with tray batch automatic transfer suitable for unmanned continuous binder removal and sintering applications.

Business Execution

Equipment Design

All our products are designed in-house, allowing for ease of detailed specification changes.

Transfer Device Adjustments

We make adjustment to suit customers’ production lines.

Team

We can change the team structure depending on the needs of the project and complete the task quickly and flexibly.

Aluminum and Non-Ferrous Metal Equipment

Aluminum and Non-Ferrous Metal Equipment New Material Development Equipment

New Material Development Equipment Metal Heat-Treatment Equipment

Metal Heat-Treatment Equipment