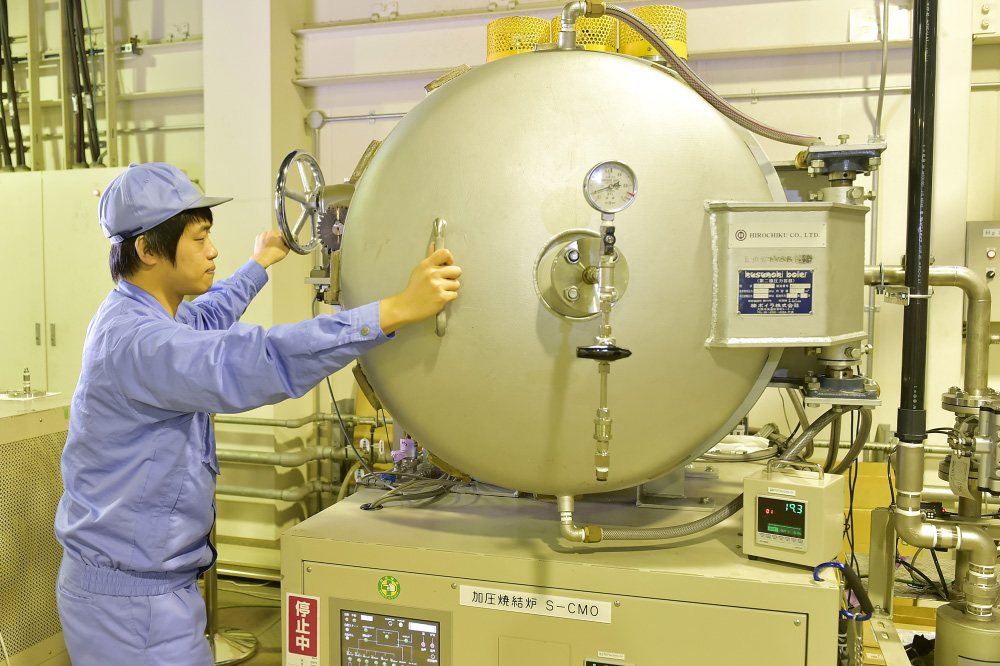

HIROCHIKU’s Technical Advisors Accept Sample Baking Tests

and Technical Consultation.

In addition to HIROCHIKU’s support using the RD Center, HIROCHIKU’s technical staff members propose optimum production processes, along with the designing and production of equipment for customers’ needs, based on HIROCHIKU’s thermal technology, which has been cultivated since its foundation, with cutting-edge powder firing technology, and vacuum atmosphere technology contributing to the development of new materials for the future.

Technical Development of Production Process

-

Flow of Technical Development Request

New Material Development

New Production Plan

-

Experiment and Development

The RD Center responds quickly to the diagnosis of optimum furnace types and the development of new furnace technology.

Sample Baking Test, Build-to-order Production, Technical Consultation

Contact Us -

Design and Production

Batch Furnace and Continuous Furnace

Powder Firing Technology / Vacuum Atmosphere Technology / Abundant Achievements

Optimal Production Process

Competitiveness

Efficiency Improvements / Energy Saving and Labor / Saving Follow Up

Achievement Example

Crystal of Technology Born from Customer Needs

- Indium tin oxide (ITO) large-scale oxygen atmosphere sintering furnace /

- Aluminum nitride (AlN) degreasing furnace and sintering furnace /

- Degreasing sintering furnace for powder metallurgy /

- Heat treatment furnace in strong magnetic fields /

- Carbon purification furnace /

- Automatic melting furnace for recycling analysis /

- Compound semiconductor synthesis furnace /

- Single crystal growing furnace, Metal distillation furnace

RD Center

Heat treatment is indispensable for the rapid progress of the development of new materials. The RD Center supports customers’ development with HIROCHIKU’s flexible ideas, satisfying required specifications.

HIROCHIKU hopes that the RD Center will be as useful to researchers as possible.

With our experienced staff and a large number of demonstration machines, which can handle sample baking tests for all materials, the RD Center will work with customers to find the best solution together.

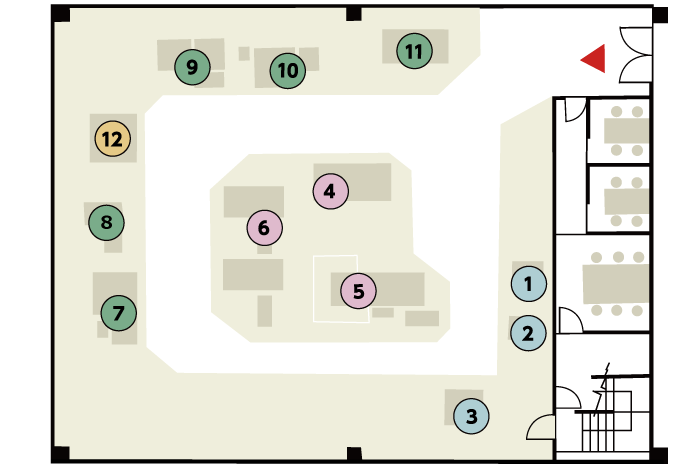

Tour in Research & Development Center

List of Sample Demo Machines* Please contact us for specific demo machine specifications

| Type | Model and Details |

|---|---|

| High-Speed Furnace Processed material: Powder and solid |

①Ultra-High-Speed, High-Temperature Melting Furnace (RMF)Max. Operating Temperature: 1,650℃ A convenient tabletop R&D furnace of elevator type, capable of introducing inert gas, and ideal for melting glass and metal.

|

②Large-Scale Fast Heating Electric Furnace (HLF)Max. Operating Temperature: 1,700℃ Optional: 1,800℃ Specifications A large-scale R&D and production furnace with good temperature distribution in the atmosphere.

|

|

③High-Speed Heating Furnace (HAF)<Max. Operating Temperature: 1,700℃ Optional: 1,800°C Specifications > The HAF Series includes an R&D and production furnace and large-scale furnace, in which various atmospheres can be easily obtained. There are also large furnaces.

|

|

| Rotary Tube Furnace Processed material: Powder |

④Rotary Tube Furnace (RTF)Max. Operating Temperature: 1,500℃ A continuous furnace that is optimal for the heat treatment of powder, used to save heat treatment time, and ideal for the pilot and full-fledged production of various powders.

|

⑤Atmosphere Rotary Tube Furnace (A-RTF)Max. Operating Temperature: 1,500℃ Making it possible to heat process various types of powders uniformly and continuously in H2 and N2 gas atmospheres.

|

|

⑥Batch Type Rotary Tube Furnace (B-RTF)Max. Operating Temperature: 1,000℃ It is possible to burn various types of powders, including metal and ceramic powders, for a long time in oxidation, reduction, and inert gas atmospheres.

|

|

| Vacuum Atmosphere Furnace Processed products: Powders, solids, and laminates |

⑦Atmosphere Hot Press Furnace (AHP)Max. Operating Temperature: 1,800℃ Max. Press Pressure: 4Ton An R&D and production furnace that employs a carbon heater and used for pressing at high temperatures in a vacuum, reduction atmosphere, and inert gas atmosphere.

|

⑧Multipurpose Atmosphere Furnace (PVF)Maximum Operating Temperature: 1,150℃ A versatile atmosphere furnace of completely sealed type using a muffle, and providing a vacuum, oxidizing or reducing atmosphere, and inert gas atmosphere.

|

|

⑨High-Temperature Vacuum Atmosphere Furnace (SVF)Max. Operating Temperature: 2,200℃ An R&D and production furnace that employs a metal heater and can perform heat treatment in a vacuum, reducing atmosphere, and inert gas atmosphere.

|

|

⑩High-Temperature Vacuum Atmosphere Furnace (CVF)Max. Operating Temperature: 1,800℃ An R&D and production furnace that employs a carbon heater and performs heat treatment in a vacuum, reducing atmosphere, and inert gas atmosphere.

|

|

| Small-scale Heating Sintering Furnace Processed material: Powder and solid |

⑪Small-Scale Heating Sintering Furnace (S-CMO)Max. Operating Temperature: 1,700℃ A sintering furnace that can be used under pressurized atmospheres in a wide range of conditions, including oxidizing and reducing atmospheres. Pressurized up to 0.9 MPa. Larger sizes are available.

|

| Condensing Furnace Processed material: Powder and solid |

⑫Condensing Furnace (OHS)Max. Operating Temperature 1,100℃ Incorporating a reflection module and halogen heater to achieve rapid heating and cooling.

|

| Sample Demonstration Machine (Installed in the Product Center) | |

| Pressurizing Furnace Processed material: Powder and solid |

Pressure Sintering Furnace (CMO)Max. Operating Temperature: 1,700℃ A sintering furnace that can be used under pressurized atmospheres in a wide range of conditions, including oxidizing and reducing atmospheres. Pressurized up to 0.9 MPa. Larger sizes are available.

|

| Large-Scale Elevator-Type Electric Furnace Processed material: Powder and solid |

Large-Scale Elevator-Type Electric Furnace (HPF)Max. Operating Temperature: 1,700℃ An elevator-type electric furnace developed to increase the size and soaking. This furnace provides uniform soaking for a large amount of sintering at high temperatures and demonstrates excellent performance for research and production.

|

Access

RD Center, Kobe Branch Office, HIROCHIKU Co., Ltd.

4-2-4 Minatojimaminami-machi, Chuo-ku, Kobe-shi, Hyogo 650-0047

TEL. +81-78-306-2960

Get off at Iryo Center Station on the Port Liner and walk for eight minutes.

Business Execution

Design

HIROCHIKU sets a baking test plan, based on the processing object and heat treatment conditions.

Site

HIROCHIKU collects fired products and resulting data with precision, according to the test plan.

Team

Our experienced technical staff will support customers.

Main Industry

- Electronic Components and Semiconductors

- Solar Panels

- Ferromagnetic Materials and Hydrogen Adsorption

- Wiring

- Fuel Cells

- Pharmaceuticals

- Optical Devices

- Catalysts

- Abrasives

- Super-High-Purity Refining

- Material and Raw Material Manufacturing

- Space Development

- Government and University Labs

Aluminum and Non-Ferrous Metal Equipment

Aluminum and Non-Ferrous Metal Equipment New Material Development Equipment

New Material Development Equipment Metal Heat-Treatment Equipment

Metal Heat-Treatment Equipment