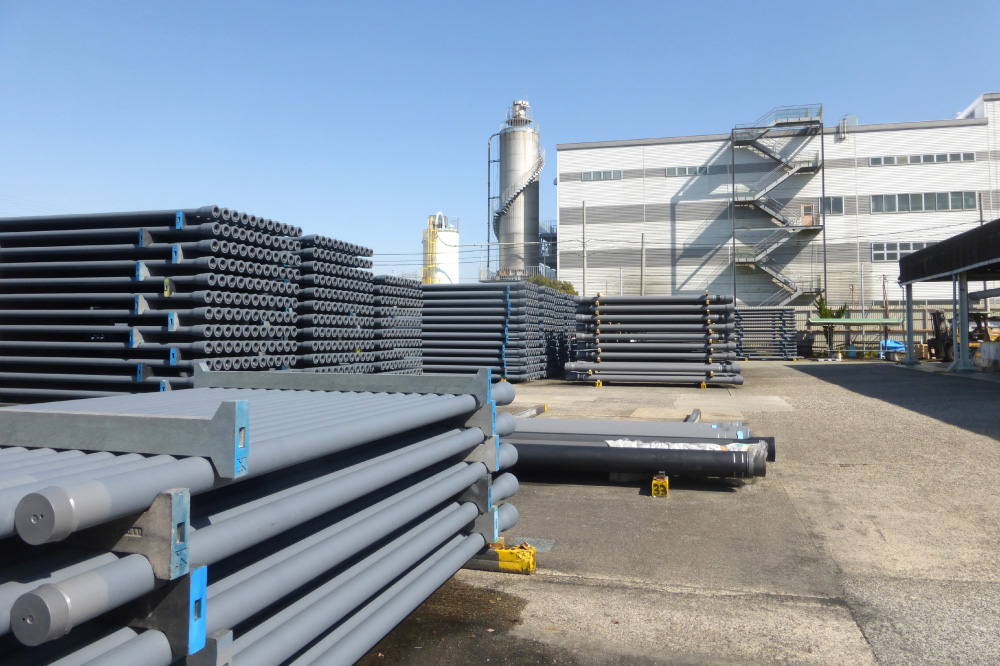

Our cast iron pipe plant team is engaged in repairing refractory components needed to melt and cast iron as well as annealing work in which iron pipe is heat treated and product fabrication work.

Features

Skill in Operating Furnaces at Heat Treatment Temperatures Required by Products

Furnace temperature control and work meander control and management are carried out precisely by means of predetermined procedures.

Skill in Operating Exterior-Surface Corrosion Prevention Systems Efficiently

Surface corrosion prevention coatings are applied in order to increase the physical resistance of surfaces to chemicals, impact, and friction.

We provide the skills needed to ensure safety, quality, and on-time delivery in these continuously operating processes.

Skill in Efficiently Machining Complex Shapes Using NC Lathes

We use NC lathes to machine key parts that are used in cast iron pipe joints.

Online Work

Annealing Furnace Operation, Product Line Work

Offline Work

Cast Iron Pipe Ring Lathe Machining Work, Cupola Refractory Material Repair Work, Annealing Furnace Repair Work

Business Execution

Annealing Furnace Operation

We carry out cast iron pipe annealing work while reliably maintaining predetermined temperatures.

Surface Corrosion Prevention Coating Work

We carry out surface corrosion prevention coating work to ensure safety, quality, and on-time delivery.

Automatic Lathe Work

We apply measurement results to increase machining precision.

Main Customers

- Kurimoto, Ltd.

Aluminum and Non-Ferrous Metal Equipment

Aluminum and Non-Ferrous Metal Equipment New Material Development Equipment

New Material Development Equipment Metal Heat-Treatment Equipment

Metal Heat-Treatment Equipment