Features

This series includes heat treatment furnaces for non-ferrous metal materials including copper, aluminum, magnesium and titanium alloys. Hydrogen, nitrogen, argon and other gas atmospheres are used. The hot gas circulation method ensures excellent temperature distribution.

BMRBell Type Bright Annealing Furnace

Vacuum purge bright annealing furnace that provides outstanding productivity using 100% hydrogen gas atmosphere. Offers higher performance than vacuum furnaces.

| Applications | Bright annealing of copper alloys (bands, strips, wires, pipes, heavy objects), aluminum foil bands, copper bands and forgings |

|---|---|

| Features |

|

| Temperature | 100 to 800℃ |

| Treated weight | 3 to 50 ton/ch |

| Atmosphere | N2+H2 after vacuum purge |

RAVHorizontal Vacuum Purge Bright Annealing Furnace

Horizontal bright annealing furnace that provides high precision and ease of use

| Applications | Clean heating of precision parts and electronic parts that require high quality |

|---|---|

| Features |

|

| Temperature | 100 to 650℃ |

| Treated weight | 50 to 500 kg/gross |

| Atmosphere | N2, Ar or H2 after vacuum purge |

RAGas Atmosphere Low-temperature Heat Treatment Furnace

Easy to use, versatile semi-automatic type

| Applications | Annealing and age hardening of copper alloys, heat treatment of magnesium alloys, annealing for stress removal and non-oxidation heating |

|---|---|

| Features |

|

| Temperature | 150 to 400℃ |

| Treated weight | 15 to 60 kg/gross |

EMPPot Type Atmosphere Heating Furnace

Pot gas atmosphere furnace that serves many purposes.

| Applications | Annealing of brass and phosphor bronze, annealing of low silicon steel plates, and solutionizing and artificial aging of magnesium alloys |

|---|---|

| Features |

|

| Temperature | 200 to 930℃ |

| Treated weight | 50 to 400 kg/gross |

| Atmosphere | N2+C3H8 or H2 |

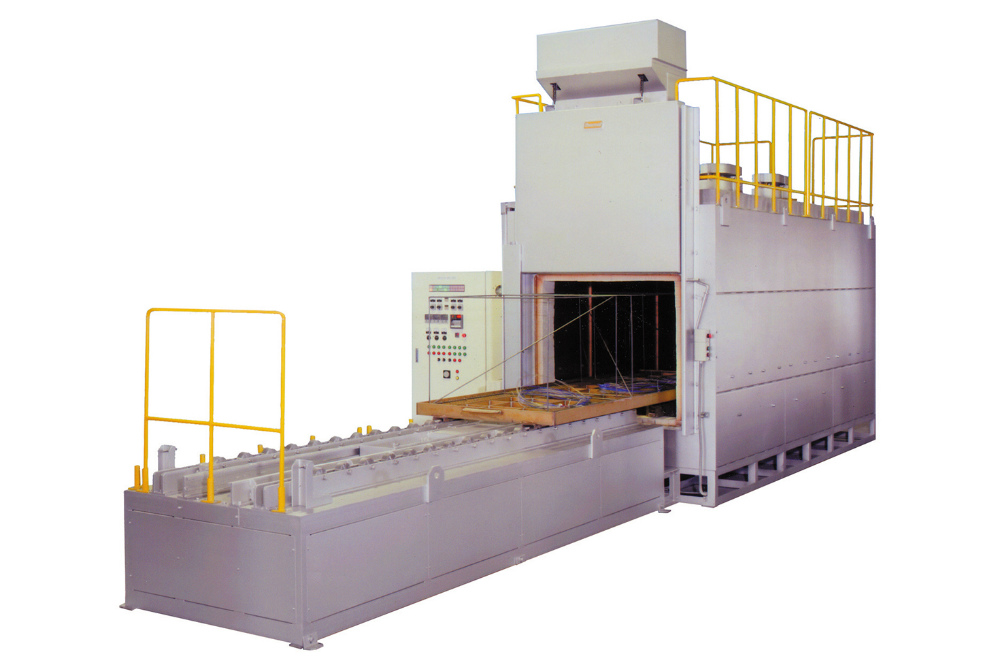

RBTBox Airflow Annealing Furnace

Highly versatile, energy-saving box furnace that serves many purposes including annealing in an air atmosphere, tempering and solutionizing

| Applications | Tempering of steel (after vacuum quenching, induction hardening, or carburizing and quenching), annealing of metals, and shrink fitting |

|---|---|

| Features |

|

| Temperature | 100 to 650℃ |

| Treated weight | 100 to 2,000 kg/gross |

| Atmosphere | Air |

About the heat treatment furnaces for non-ferrous metals

(PMR/RAV)

Aluminum and Non-Ferrous Metal Equipment

Aluminum and Non-Ferrous Metal Equipment New Material Development Equipment

New Material Development Equipment Metal Heat-Treatment Equipment

Metal Heat-Treatment Equipment