Recommended Thermal Standard Series of Heat Treatment

Next-Generation Nitriding Potential Control System

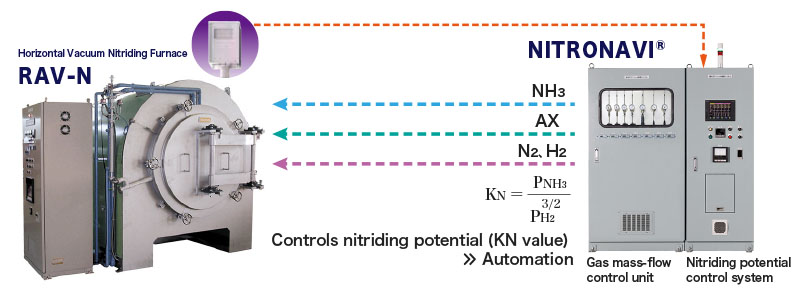

through HIROCHIKU CO.,LTD. and PARKER NETSUSHORI KOGYO CO., LTD. CollaborationEquipped with NITRONAVI® RAV-N

The RAV-N equipped with NITRONAVI® is the ultimate solution for achieving precise control and highly efficient nitriding processing.

Features

Achieves low cost, short delivery time, and high reliability through a high standardization rate.

Flexible response to specific needs with a wide range of options.

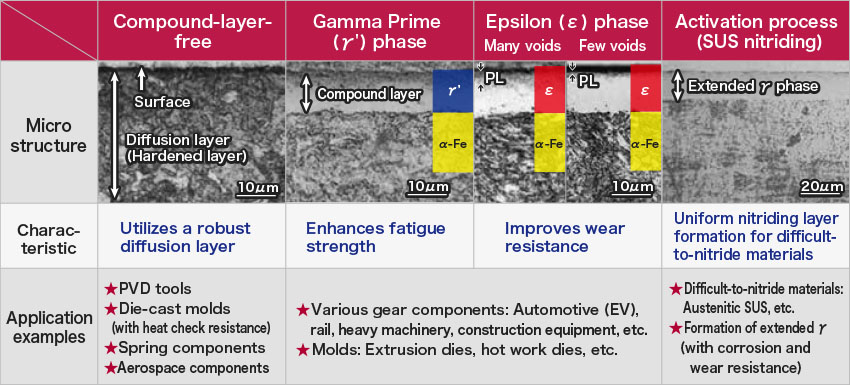

Provides optimal recipes to achieve the best material properties.

Support for stable operation by service engineers from HIROCHIKU CO.,LTD. and PARKER NETSUSHORI KOGYO CO., LTD..

Main options

- Remote monitoring systemUnmanned operation during nights and holidays

- Optimal recipe creationEnhanced functionality of processed items

- Regular maintenance and inspection serviceStable operation

- AX gas generatorExpansion of gas infrastructure

- In-furnace pressure control systemFurther reduction in gas consumption

Specifications

NITRONAVI®

| Model | LT | PN | NC | |

|---|---|---|---|---|

| Possible processing | Nitriding process | Nitriding process | Nitriding process/Soft nitriding process | |

| Operational advantages | Fully automatic processing | △ | ○ | ○ |

| Reduction in ammonia consumption | ━ | ○ | ○ | |

| Gases used | Required | NH3 | NH3、AX | NH3、AX、CO2 |

| Useful | AX | N2 | N2 | |

Horizontal scrolling enabled.

RAV-N

| Model | Effective dimensions W×H×L mm | Processing capacity kg/gross | Operating temperature ℃ | Electric capacity kW | Furnace dimensions W×H×L mm | Atmosphere | |

|---|---|---|---|---|---|---|---|

| Heater | Others | ||||||

| RAV-30N | 300×300×400 | 50 | 100~650 | 20.6 | 5 | 2340×2340×2300 | After vacuum purge Various gase |

| RAV-50N | 400×400×600 | 100 | 42 | 6.1 | 2430×2440×3700 | ||

| RAV-70N | 600×600×900 | 450 | 70 | 10 | 3000×2590×4240 | ||

| RAV-100N | 900×900×1300 | 800 | 120 | 16 | 3330×3000×4760 | ||

Horizontal scrolling enabled.

Solution

Achieves the highest quality through advanced compound phase control

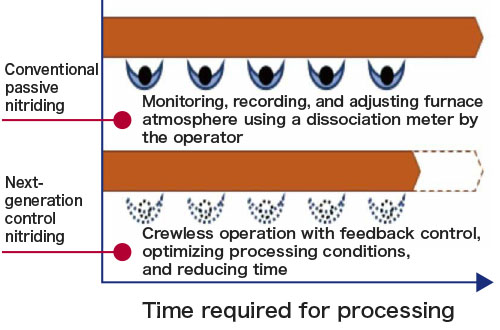

Achieves high-quality precision through real-time atmospheric automatic control (low variability)

Reduces labor hours and enables crewless, labor-saving operation

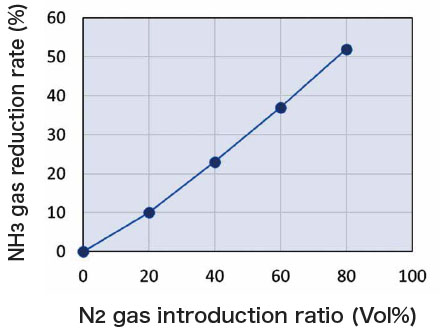

Reduces NH3 consumption through multi-gas control

Aluminum and Non-Ferrous Metal Equipment

Aluminum and Non-Ferrous Metal Equipment New Material Development Equipment

New Material Development Equipment Metal Heat-Treatment Equipment

Metal Heat-Treatment Equipment