HIROCHIKU’s heat treatment service performs heat treatment processing of

customers’ products at HIROCHIKU’s plant.

Thermal Heat Treatment Contract Service

- You may require heat treatment, but not every day.

- You may not be able to purchase heat treatment equipment because you manufacture products in small quantities.

- You may have no person in charge of heat treatment technology.

- You may have no human resources with knowledge of heat treatment.

- You may have no time to learn.

- You may have no place to install heat treatment equipment in your workplace.

- You may know what you want to manufacture, but you may not know how to go about it.

- You may need to consult someone about heat treatment anyway.

Please leave all your Thermal heat treatment processing to us.

HIROCHIKU derives optimal heat treatment conditions for customers’ product processing and performs high-quality brightening heat treatment using hydrogen gas.

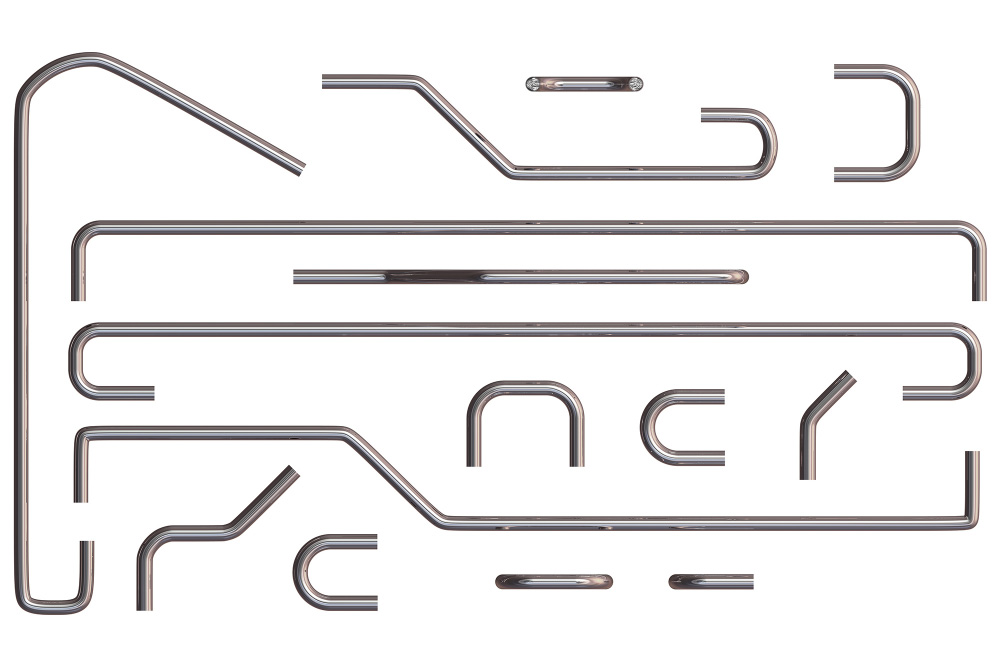

Available and Acceptable Heat Treatment Processing Items

Annealing

It is possible to reduce (soften) the hardness of metallic materials. This is a process that is often performed to facilitate post-processing.

Target processing example

- Flexible pipe

- Pipes for automotive parts

- Watch parts

- Bellows

- Various pressed parts

Types of heat-treatable metals

Austenitic stainless steel (e.g., SUS304, SUS316, and SUS310S)

Solution Treatment

Solution treatment eliminates residual stress and hardening resulting from processing work and improves workability and corrosion resistance. This is a process often performed after processing stainless steel products.

Target processing example

- Stainless pipe

- Western tableware

- Watch stainless steel band

- E.g., various pressed parts

Types of heat-treatable metals

Austenitic stainless steel (e.g., SUS304, SUS316, and SUS310S)

Quenching

Quenching makes it possible to increase the hardness of metal products. It is a process that is often performed to make them more difficult to break.

Target processing example

- Kitchen knives

- Scissors

- Disc brakes

- Industrial tools

- Diverse types of cutlery

- Micro shafts for small motors, etc.

Types of heat-treatable metals

Martensitic stainless steel, etc. (SUS420, 440, 403, etc.)

Brazing

Brazing makes it possible to join base metals together precisely using a brazing material. This process is often applied to the joining of materials that are difficult to weld, such as dissimilar materials, small parts, and materials of complicated shapes.

Target processing example

- Heat exchangers

- Auto parts

- Hydraulic equipment

- Gas appliances

- Building construction parts

- Agricultural machinery parts

- Stainless steel filters

Types of heat-treatable metals

Stainless steel, alloy steel, iron, copper, etc.

Heat Treatment Equipment

Heat treatment furnace No. 6 for brazing in non-oxidizing furnaces (BCE270-100-2400Q)

Heat treatment furnace No. 7 for stainless steel brightening (BCE350-120-4000Q)

HIROCHIKU uses two in-house heat treatment furnaces, depending on material and purpose.

HIROCHIKU accepts Thermal heat treatment using a heat treatment furnace developed and manufactured in-house.

This straight furnace excels at the brightening treatment of extended objects. Of course, small parts are also brilliantly finished.

This continuous furnace enables mass-production processing.

A 3000-m³ hydrogen tank is provided, so it is possible to process the heat treatment work very beautifully, at a low cost.

Heat Treatment Plant Information

HIROCHIKU performs heat treatment processing at the new heat treatment factory in HIROCHIKU’s Nasu Plant in response to customers’ requests.

The plant is located in the northern Kanto area, a gateway to the Tohoku region, which makes it possible to reduce the cost of transporting metal materials to be treated.

| Location | Nasu Plant, HIROCHIKU CO., LTD. 767 Hachisu, Otawara-shi, Tochigi 324-0244 TEL. +81-287-54-4130 FAX. +81-287-54-3430 |

|---|---|

| Nearest interchange | Yaita, Nasu, and Nishinasuno Ten-ton trucks are accepted. |

HIROCHIKU offers the purchase of heat treatment equipment to customers who are considering the introduction of the same for increasing the number of heat treatment products, shortening the time of delivery, and acquiring in-house technology. At the time of introduction, HIROCHIKU also offers sample test conditions.

Aluminum and Non-Ferrous Metal Equipment

Aluminum and Non-Ferrous Metal Equipment New Material Development Equipment

New Material Development Equipment Metal Heat-Treatment Equipment

Metal Heat-Treatment Equipment